اندازه گیری پمپ وکیوم

مطمئن شوید که پمپ خلاء شما اندازه گیری می کند

تکنسین های سرویس باید هر زمان که سیستم را به جو باز می کنند، سیستم تبرید را به طور کامل تخلیه کنند. پمپ های خلاء و گیج های میکرونی ابزاری هستند که برای این کار باید استفاده کنید. آیا مال شما در شرایط کار خوب است؟

تخلیه سیستم فقط یک سرویس خوب عقل سلیم است. قبل از افزودن مبرد باید بخار آب، نیتروژن و اکسیژن موجود در هوا را حذف کنید. اگر هوا را در سیستم بگذارید، در کندانسور جمع میشود و فضا را اشغال میکند و باعث میشود فشار سمت بالا بالاتر از حد معمول باشد.

هر بخار آب موجود در هوا ممکن است یخ بزند و محدودیت ایجاد کند، معمولاً در خروجی دستگاه اندازه گیری. همچنین بخار آب و اکسیژن می توانند مخلوط شوند و اگر به اندازه کافی گرم شوند ممکن است اسید در سیستم ایجاد کنند.

تخلیه کامل سیستم با استفاده از پمپ خلاء با کیفیت خوب و گیج میکرون می تواند از وقوع این اتفاق جلوگیری کند. بسیاری از تولیدکنندگان تبرید توصیه می کنند سیستم را تا سطح 500 میکرون تخلیه کنید. این به طور معمول تضمین می کند که سیستم کاملاً گاز زدایی و آبگیری شده است.

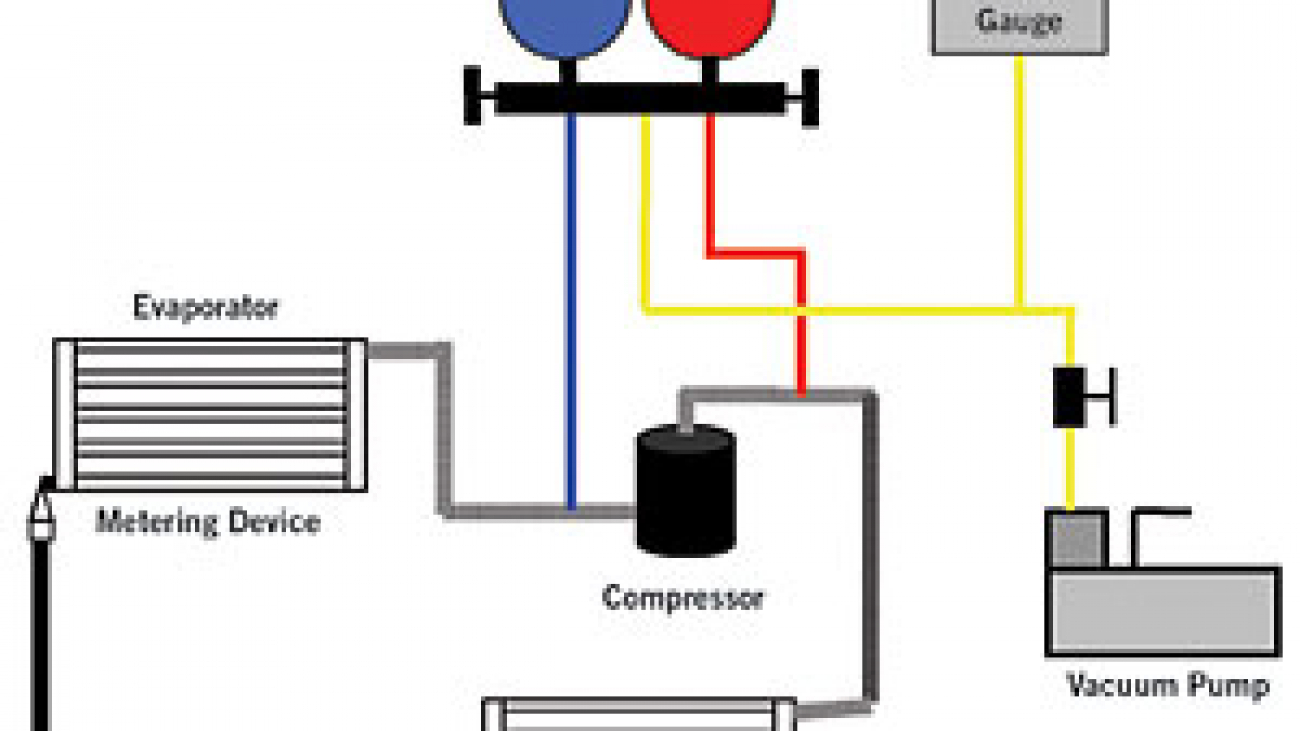

شکل 1. شیر بین گیج میکرون و پمپ خلاء به تکنسین اجازه می دهد تا آزمایش خلاء ایستاده را انجام دهد.

تعمیر و نگهداری ابزار

مانند بسیاری از ابزارهای سرویس، پمپ های خلاء و گیج های میکرونی باید به طور منظم نگهداری شوند. بدون تعمیر و نگهداری منظم، این دستگاه ها ممکن است از کار بیفتند – طبق قانون مورفی، معمولاً زمانی که بیشتر مورد نیاز هستند.

روغن پمپ های وکیوم باید به طور منظم طبق توصیه سازنده تعویض شود.

سنسورهای مورد استفاده در بسیاری از گیج های میکرونی ممکن است نیاز به تمیز کردن داشته باشند.

باز هم، همیشه از رویه های توصیه شده سازنده برای تمیز کردن این سنسورها پیروی کنید. بسیاری از سازندگان توصیه می کنند سنسورها را با الکل تمیز کنید. این کار را می توان با افزودن چند قطره به اتصال فلر 1/4 اینچی انجام داد، سپس دستگاه را به آرامی تکان داد و اجازه داد در هوا خشک شود.

همراه با تعمیر و نگهداری منظم، یک تکنسین باید همیشه عملکرد هر دو پمپ خلاء و گیج میکرون را قبل از استفاده از آنها در سیستم بررسی کند. بهتر است قبل از استفاده از هر یک از این دستگاهها در سیستم و اتلاف وقت در کار، مشکلی را در هر یک از این دستگاهها کشف کنید.

هنگامی که پمپ خلاء و گیج میکرون را راه اندازی می کنید، مطمئن شوید که یک شیر بین سیستم و راه اندازی پمپ خلاء/میکرون گیج نصب شده است. به طور معمول می توانید از گیج های منیفولد تبرید برای این منظور استفاده کنید.

همچنین باید یک شیر بین گیج میکرون و پمپ خلاء وجود داشته باشد (شکل 1). این به یک تکنسین اجازه می دهد تا یک آزمایش خلاء ایستاده را پس از رسیدن به سطح 500 میکرون روی سیستم انجام دهد.

تست پمپ

پیروی از این روش ساده تست می تواند در زمان شما صرفه جویی کند. اگر پمپ خلاء مشکل داشت، ممکن است جارو برقی را راه اندازی کنید و سیستم را به درستی تخلیه نکنید. اگر مشکلی در گیج میکرون وجود داشت، ممکن است پمپ خلاء را بیشتر از زمانی که برای دستیابی به یک سیستم تخلیه مناسب لازم است کار کنید. برای تست پمپ موارد زیر را انجام دهید:

قبل از اینکه پمپ خلاء و گیج میکرون را به سیستم باز کنید، شیر بین سیستم و راه اندازی پمپ خلاء/میکرون گیج را ببندید و پمپ خلاء را روشن کنید. با این کار فقط یک خلاء روی شیلنگ جاروبرقی و گیج میکرون می کشد.

گیج میکرون باید سطح 500 میکرون را در مدت زمان نسبتاً کوتاهی ثبت کند. اگر اینطور نیست، گیج میکرون، پمپ خلاء یا شیلنگ متصل کننده مشکل دارد. قبل از باز کردن پمپ خلاء به سیستم، باید تشخیص دهید کدام یک از این دستگاه ها باعث ایجاد مشکل شده و آن را برطرف کنید.